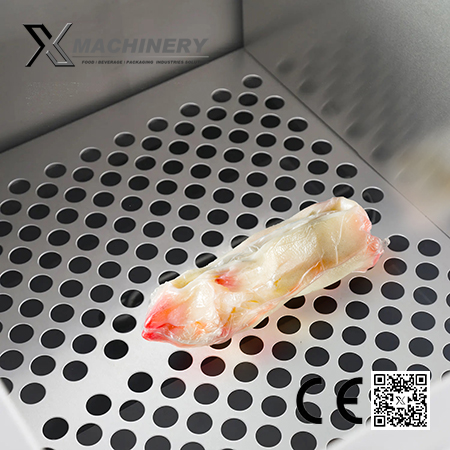

Hot dip tanks use water immersion to remove excess material and wrinkles from around vacuum-packed foods. This is a great way to improve the sales and presentation of your vacuum packaged products. This versatile machine works with vacuum chamber machines and shrink bags and can be programmed for both manual and automatic use, making it ideal for small to medium-sized operations.

feature:

Safety Sensor: Low water cut-off protection and alarm light.

Water Tank Cover: Helps prevent external rims and maintains water temperature in the tank.

Warehouse: Equipped with cargo so you can move the machine safely and secure it in place as needed.

Customizable features: Fast water soaking time to meet your packaging needs.

Dual drive mode: Machine programming can operate manually or automatically.

Manual Mode: Cycle actuator start via simple push button.

Automatic mode: Switch to automatic mode and the machine will cycle itself with a default delay to allow for loading time.

Thermal insulation: Improve thermal insulation, avoid heat loss and reduce alcohol.

Convenience: Easily fill and drain the water tank, easy access to machine parts, and simple maintenance.

Model no: ST-6050

Voltage :220-380V 50/60Hz

Power: 7X2kW

Temperature: 0-99℃ adjustable

Control automatic/manual functions

Automatic 0-99 seconds adjustable up and down time, automatic cycle start

Manual up and down jog function

Lift up and down: 330mm

Water tank: 0.14m2

Size 500X600X498mm

Material SUS 304

Maximum load: 100kgs

- Video source:

| * Subject: | |

| * Message: | |

| * Contact: | |

| * Email: | |

| CompanyName: | |

| * Phone: | |

| Fax: | |

| Address: | |

中文版

中文版